Metal polishing and bright finishing are surface finishing mechanical treatments. These particular operations mainly carried out using automatic or manual machines with special brushes and/or belts. Roditor & Philadelphia satisfies its customer’s requirements by adopting different polishing techniques depending on the nature of the product and its use. In addition to the industrial metal, the company is able to prepare the surface for the varnishing phase and it carries out the technical polishing on plastic materials, with varnishing systems equipment and so on. The main industrial metal polishing techniques are the shot peening with blast machines, the tumbling and the sandblasting.

- The shot peening is the surface hammering of a material with a strong jet of metal beads, spherical or angular, and it leads to a surface compression on the treated items.

- The tumbling equipment are suitable for every industrial treatment of deflashing, grinding and bright finishing of metals and mirror finishing of the items.

- The metal sand blasting is a finishing operation, carried out with the application of sand in order to improve the surface aspect of metal pieces or parts of them. It is adopted on steel, metallic alloys, cast iron, wood, ceramic, stones and marble.

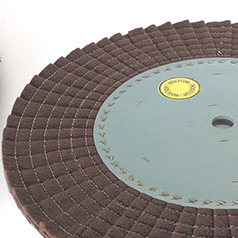

Roditor & Philadelphia’s buffs for metal polishing are ventilated sisal or cotton buffs, corrugated sisal or cotton buffs, stitched and pleated buffs. Sisal buffs are used in the roughing and polishing treatments on stainless steel, iron, brass and aluminium. Cotton buffs, instead, are used in bright and mirror finishing treatments of stainless steel, iron, aluminium, plastic and precious metals.

The production range of the company includes polishing buffs made of sisal, cotton, Rodiflex, steel wires and Tampico of a diameter between 80mm and 1600 mm, with or without impregnation and with countless variation of sewing (simple section, ventilated, corrugated, stitched and pleated). In addition, the production includes Rodiflex wheels, small sisal and cotton buffs, brushes and cylinders.

Solid and abrasive compounds produced by the company are designed to be used in roughing , polishing and mirror finishing operations on different kinds of metals. Moreover, Roditor & Philadelphia offers solutions realized for special treatments and applications

- Solid TALLOW compound

- Liquid TALLOW compound

- Solid abrasive compound BIANCA S/105

- Liquid abrasive compound BIANCA PLAST

- Solid abrasive compound BIANCA S/M

- Solid abrasive compound GRANITO

- Solid abrasive compound P 286/S

- Solid abrasive compound CRIS 190/S

- “in cold” paste

- FIORE/S paste

- Cleaning paste for hands.

Furthermore, the company provides the required components for the liquid abrasive compound spraying: tanks, filters, pumps, low and high pressure guns, feeding, adapters, manometers, electro-valve, nozzles and controls. The company provides spare parts and manuals for its pumps and guns.