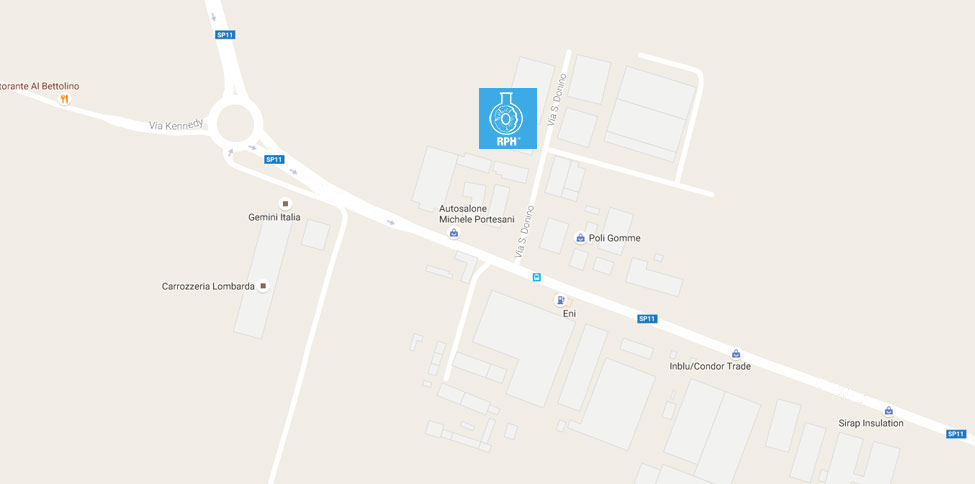

Roditor & Philadelphia s.r.l. - Via San Donnino, 13 I - 25028 Verolanuova (BS) ITALY - Tel. +39.030.931211 Fax +39.030.931768

Italian Customers Management: Mrs. Pierangela Azzini This email address is being protected from spambots. You need JavaScript enabled to view it.

Export Sales Office: Mrs. Elisa Pe' This email address is being protected from spambots. You need JavaScript enabled to view it.

Technical Office div. Compounds: Mrs. Daniela Brusinelli This email address is being protected from spambots. You need JavaScript enabled to view it.

Technical Office div. Buffs: Mr. Simone Scotuzzi This email address is being protected from spambots. You need JavaScript enabled to view it.

The abrasive compound must leave the tank at 4-5 atm; to operate low pressure guns use 5-6 atm; for high pressure guns follow the manufacturer’s instructions.

The low pressure gun sprays the compound at a force equal to that of the air supply to which it is connected (5-6 atm); the high pressure gun, which incorporates a multiplier, sprays the compound at a pressure 20-30 times superior than that of the air supply.

High pressure gun is necessary when the compound sprayed by a normal pressure gun is wasted by the polishing mops centrifugal force. High pressure gun saves a lot of compound and due to the different angles of the nozzles (40°, 65°, 90° and 120° can be chosen) one sinlge gun can spray the polishing wheel from 2 to 50 cm. wide.

The choise between the two types depends on the different purchase prices and the specific requirements of the work to be done.

The use of an automatic distribution system will give the following advantages:

We provide the components necessary to the spraying of liquid abrasive compounds: pressure tanks, filters, pumps, low and high pressure sprayguns, feeder, adaptors, manometers, electric valves, nozzles and so on. For pumps and sprayguns, we provide spare parts and instruction manuals.

Minisiletto lt 115 »The best way of using liquid abrasive compounds is that of spraying them with low or high-pressure guns, by means of a centralized system, so as to obtain a light, regular and uniform supply.

The supply of solid abrasive compound is made by means of a pneumatic feeder, mod. COSMEC, applied on both manual and automatic polishing machines.

HIGH PRESSURE SPRAY GUN 60P16evo

The range of the special compounds includes specific solutions for special applications and operations, such as the tallow compound to lubricate the belts and the flap wheels of abrasive cloth; the solid compounds to bright finish polyester and plastic, marble, granite and polyurethane shoes soles.

Thanks to the high abrasive and lubricating power, the solid abrasive compounds are suitable for the polishing operations of all metals, both on manual and automatic and semi-automatic polishing machines.

The solid compounds with natural abrasives are suitable for the surface treatment of the brass and other alloys, while the solid compounds with synthetic abrasives have a high mirror finishing power on stainless steel and ferrous metals.

The supply of solid abrasive compounds is made by means of a pneumatic feeder – model “COSMEC”, applied on both manual and automatic polishing machines – which feeds the compound on to rotating buffs in such a way to obtain a perfect dosing, a correct pressure on the buffs, less waste of unused compound and, in case of manual machine, it allows the operator to have both hands free. The feeder can employ compound bars having the max dimensions of 160 mm., length 500 mm., height 50 mm.

Thanks to the homogeneity, the adherence to the polishing buffs and to the lubricating power that reduces the buffs wearing, our liquid abrasive compounds are suitable for the polishing and mirror finishing operations of various metals on automatic and semi-automatic machines, provided with a centralized feeding system.

The best way of using liquid abrasive compounds is that of spraying them with low or high pressure guns, by means of a centralized system – with pressure tank of 50 or 100 litres or tank “Siletto” with a pump – so as to obtain a light, regular and uniform supply.

Roditor & Philadelphia is today one of the most important manufactures of products for robotic and manual polishing and metal surface treatment in the world.

The historic company, Confezioni Dischi Roditor, was born in 1958 in Verolanuova with the objective of supplying the local customers in the metal polishing.

During the years Roditor & Philadelphia gained greater stature and popularity on the national market, and the products began to be used by a growing number of companies.

At the beginning of the 70’s, to satisfy the requirements of the customers, Roditor & Philadelphia decides to complete the production range of buffs introducing the production of the abrasive compounds, with the assistance of an expert manufacture who was operating into the local market. In 1972, the partnership between Mr. Giovanni Pugnetti and Confezioni Dischi Roditor, forms the company Philadelphia Chemical, the name took its basis from the street the company was set up.

In 1980 the merger between Confezioni Dischi Roditor and Philadelphia Chemical created Roditor & Philadelphia birth. In 1991 Roditor & Philadelphia put together the production department of buffs and abrasive compounds and in 1999 combine the production, the management and the sales offices into the same facility located in the present headquarter in Via San Donnino 13 Verolanuova (BS).

In 2002 the company obtains the Certification UNI EN ISO 9001 for its Quality Management and in 2016 the certification OHSAS 18001 for its Occupational Health and Safety Management System.

In 2020 Roditor & Philadelphia has successfully passed the certification of its Health and Safety Management System to the requirements of the ISO 4500101 standard.

Today Roditor & Philadelphia solutions for the surface treatment and metal finishing are used all over the world.

The continuous and steady research, the technical improvements of our equipments, the use of high quality raw materials are the basic principles of the company philosophy.

Thanks to this way we help our customers to reach operational advantages, such as the upgrading finishing, the progress of output results, the cost optimization, the working cycles simplification.

The increase of research and development activities; the raise of the standard production and the level of customer’s satisfaction; the investment in the production and storing areas; the investment in new and up-to-date machineries are the main concepts of the quality policy of our company, which is oriented to the success of our Customers.