Roditor & PHILADELPHIA

Roditor & Philadelphia has been producing abrasive compounds and buffs for the surface treatment and metal finishing since 1958.

Our wide range of products includes: solid and liquid abrasive compounds and buffs from 80 to 1600 mm. in diameter in many variations of materials and types.

We aim at high quality items through the constant research to satisfy the requirements of Italian and Foreign customers.

The production range

of Roditor & Philadelphia

BUFFS

Cotton Buffs

RPH COTTON CLOTHS

APPLICATIONS

The Sisal buffs

Ventilated Buffs

Stitched sisal buffs

Abrasive Compounds Liquid & Solid

Abrasive Compounds

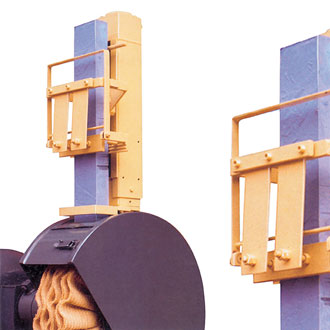

Spraying and feeding system

Solid compounds

Accessories

For mounting mops and brushes on the polishing machine’s shaft, it is necessary to use: sheet metal centres / cardboard spacers / locking flanges

Plaited sisal brushes.

- ventilated sisal buffs

- corrugated sisal buffs

- pleated sisal buffs

- stitched sisal buffs

- Stress issues